|

|

|

|

|

|

|

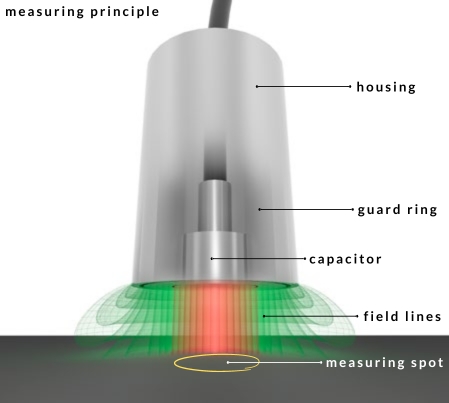

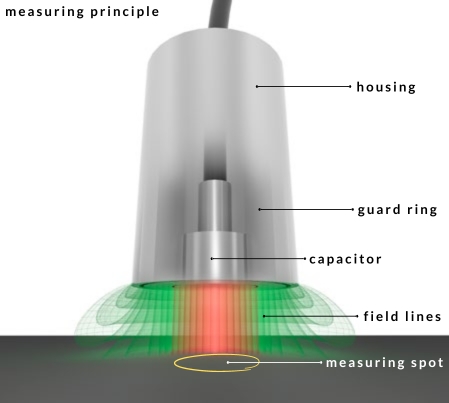

What is the measuring principle of capacitive displacement sensor?

|

|

A capacitive displacement sensor is a non-contact sensor used to measure the change in displacement, position and thickness measurement of an object by detecting variations in capacitance.

The principle of capacitive displacement sensor is based on the formation of an electric field between two electric plates, with a dielectric material between them. If a constant alternating current flows through the sensor capacitor, the amplitude of the alternating voltage on the sensor is proportional to the distance between the capacitor electrodes. The alternating current is demodulated and output as an analog signal.

|

|

|

|

The use of capacitive sensors

|

|

These sensors are widely utilized in various industries, such as automotive, aerospace, manufacturing and research, due to their high precision, sensitivity and reliability.

The sensors measure against all electrically conductive materials and with appropriate electronic circuitry even against insulators.

Capacitive sensors work in clean environments.

|

|

|

Benefits of the measuring principle

|

-

Wear-free and non-contact measurement Wear-free and non-contact measurement

-

Distance and thickness measurements on conductive and non-conductive objects Distance and thickness measurements on conductive and non-conductive objects

-

Unmatched accuracy and stability Unmatched accuracy and stability

-

High bandwidth for fast measurements High bandwidth for fast measurements

-

Ideal for industrial environments, magnetic fields and vacuum Ideal for industrial environments, magnetic fields and vacuum

|

|

|

Unmatched precision

|

|

Practice shows that capaNCDT measuring systems achieve excellent results in terms of linearity, repeatability and resolution. While sub-micrometer precision is reached in industrial environments, high-precision sub-nanometer measurements are carried out in clean environments. |

|

|

Modern and user-friendly controller technology

|

|

Modern capaNCDT controllers are the ideal basis for different fields of applications. Various interfaces and ease of use via web interface allow for a fast integration into the respective application environment.

|

|

|

|

Overview

|

-

Active guard ring electrode Active guard ring electrode

-

Fast sensor replacement without calibration Fast sensor replacement without calibration

-

Largest product range worldwide (flat sensors, sensors with integrated cable, sensors with thread…) Largest product range worldwide (flat sensors, sensors with integrated cable, sensors with thread…)

-

Extremely high stability Extremely high stability

-

Measuring ranges 0.05 to 10 mm Measuring ranges 0.05 to 10 mm

-

Resolution 0.04 nm Resolution 0.04 nm

-

Temperature stability 11 ppm/°C Temperature stability 11 ppm/°C

|

|

|

|

|

Capacitive thread sensors for demanding installation scenarios

capaNCDT sensor

Measuring ranges 0.5 / 1.25 / 2 / 3mm Measuring ranges 0.5 / 1.25 / 2 / 3mm

Socket connection Socket connection

Mounting via internal thread or screw nut Mounting via internal thread or screw nut

|

|

|

|

|

|

|

Compact & capacitive single-channel system

capaNCDT 6110

Measuring ranges 0.05 -10 mm Measuring ranges 0.05 -10 mm

Linearity 0.2 % Linearity 0.2 %

Resolution 0.01 % Resolution 0.01 %

Frequency response up to 20 kHz (-3 dB) Frequency response up to 20 kHz (-3 dB)

|

|

|

|

|

|

|

Modular multi-channel system for highest precision

capaNCDT 6220

Measuring ranges 0.05 -10 mm Measuring ranges 0.05 -10 mm

Resolution 0.0005 % Resolution 0.0005 %

Frequency response up to 20 kHz (-3 dB) Frequency response up to 20 kHz (-3 dB)

Digital data rate 4 x 3.9 kSa/s Digital data rate 4 x 3.9 kSa/s

|

|

|

|

|

|

|

Capacitive multi-channel system for highest resolution

capaNCDT 6500

Measuring ranges 0.05 -10 mm Measuring ranges 0.05 -10 mm

Linearity 0.05 % Linearity 0.05 %

Resolution 0.000075 % Resolution 0.000075 %

Frequency response 8.5 kHz (-3 dB) Frequency response 8.5 kHz (-3 dB)

Temp. stab. 9 ppm/°C (controller) Temp. stab. 9 ppm/°C (controller) |

|

|

|

|

|

|

Active capacitive measuring system for long signal transmission paths

capaNCDT 61x4

Measuring ranges 2 mm Measuring ranges 2 mm

Linearity max. 2um Linearity max. 2um

Resolution max. 0.3um Resolution max. 0.3um |

|

|

|

|

|

|

Capacitive measuring system for industrial applications

capaNCDT 61x0/IP

Measuring ranges 0.5 | 1 | 1.25 | 2 | 3 | 4 | 6 Measuring ranges 0.5 | 1 | 1.25 | 2 | 3 | 4 | 6

Linearity max. 1 µm Linearity max. 1 µm

Resolution max. 0.05 µm Resolution max. 0.05 µm |

|

|

|

|

|

|

For precise thickness measurements of plastics

combiSENSOR

One-side thickness measurement of plastic films and coated metals One-side thickness measurement of plastic films and coated metals

Target thickness: 40 μm to max. 6 mm Target thickness: 40 μm to max. 6 mm

Integrated temperature measurement for output of sensor temperature Integrated temperature measurement for output of sensor temperature

Temperature range (sensor) -10 °C … +85 °C Temperature range (sensor) -10 °C … +85 °C

Integrated function to determine the permittivity Integrated function to determine the permittivity |

|

|

|

|

|

|

Measuring the Disc Thickness Variation (DTV)

capaNCDT TDTV

Multi-track thickness measurements Multi-track thickness measurements

Comprehensive software with real-time evaluation Comprehensive software with real-time evaluation

Dynamic measurements up to 20 kHz Dynamic measurements up to 20 kHz

For test benches, road tests and quality assurance For test benches, road tests and quality assurance

|

|

|

|

|

|

|

Robust measuring system for mobile gap measurement

capaNCDT TMD6-22

High accuracy & intuitive operation High accuracy & intuitive operation

Preset measurement modes for immediate operational readiness Preset measurement modes for immediate operational readiness

Comprehensive sensor portfolio Comprehensive sensor portfolio

Ideal for mobile applications in service and maintenance tasks Ideal for mobile applications in service and maintenance tasks

|

|

|

|

|

|

Wear-free and non-contact measurement

Wear-free and non-contact measurement