|

What is a bottle cap torque tester?

In bottle capping applications, quality assurance engineers want to ensure that consistent force and torque are applied in bottle caps, which is key to reducing product rejection rates.

The capping torque is not only important to ensure that the bottle is shipped properly sealed to avoid leaking during transportation, but bottle cap torque tester for repeatable measuring of opening & closing torque of bottle caps are paramount in child-resistant safety caps.

Further, systems that require sanitized or sterilized packaging, verification of successful cap torque measurement is critical for seal validation and quality control.

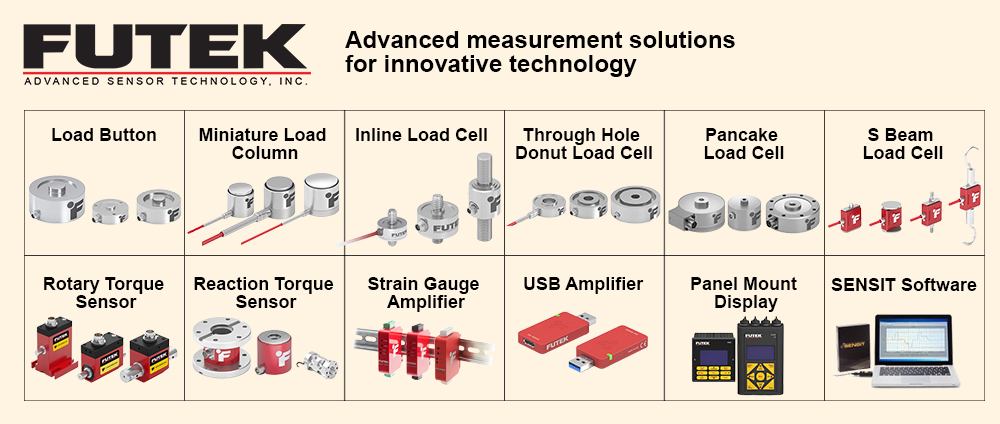

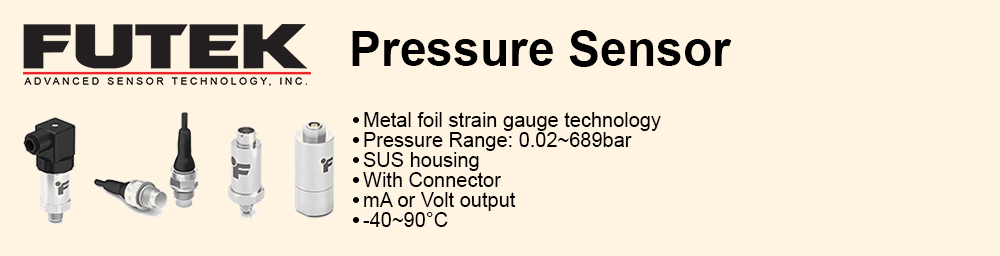

Why use a FUTEK sensor in your cap torque meter application?

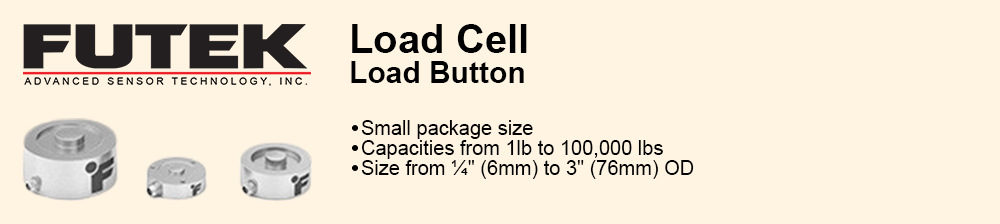

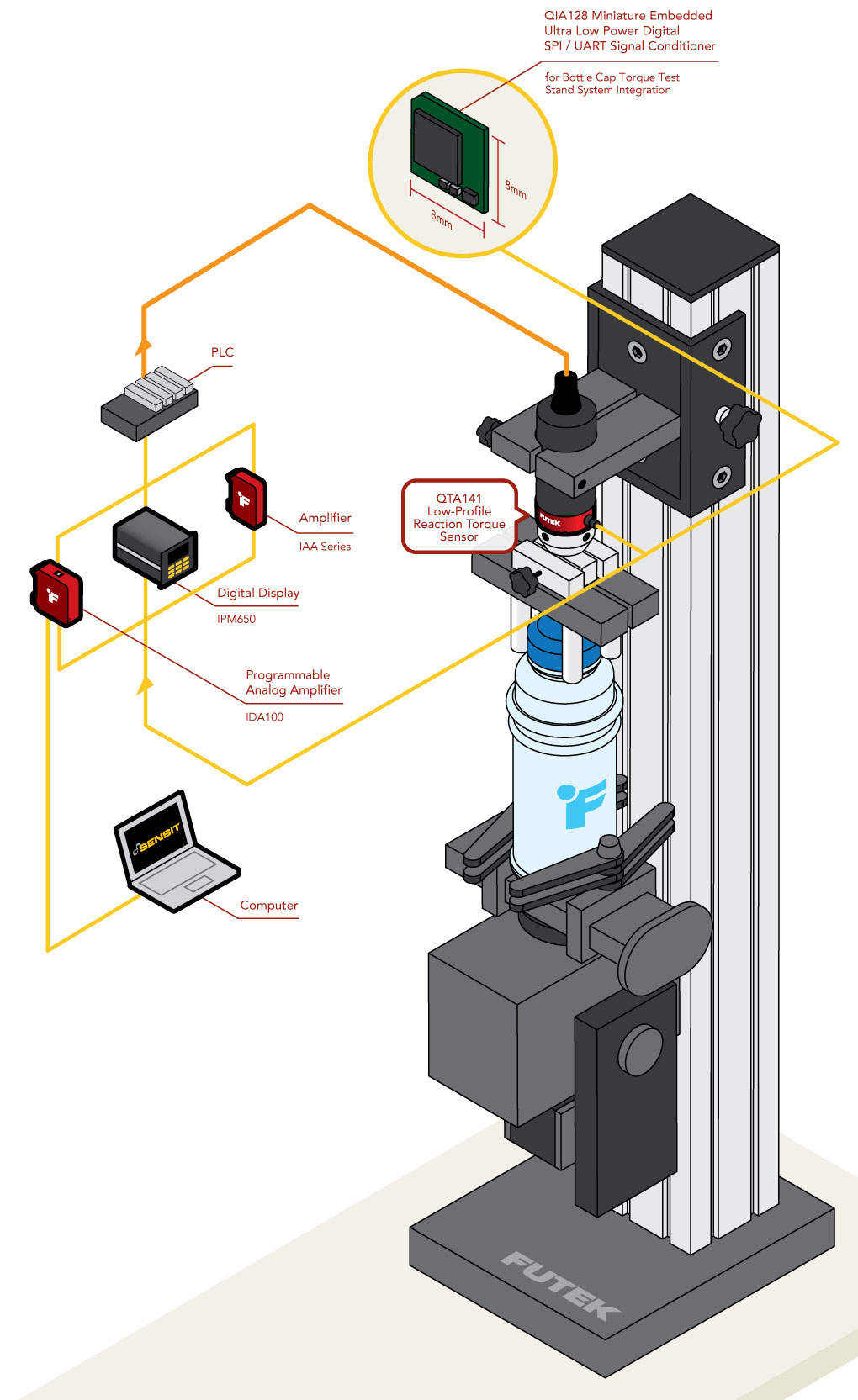

To accomplish this, a micro reaction torque sensor is used in the capping press as a cap torque meter to ensure precision, consistency, and seal integrity. FUTEK cap torque tester is ideally suited for basic clockwise and counter-clockwise bottle torque tests.

FUTEK QTA141 Reaction Torque Sensor measures insertion and removal torque of bottle cap up to 2 Nm with an accuracy of ±0.5%. Due to its super low profile with only 10 mm height, it does not stack up in the existing assembly construction and does not add unnecessary height to the test stand. Temperature-compensated and constructed of all aluminum, this torque sensor is able to achieve an impressive 0.5% nonlinearity and yet provide 150% overload protection.

If your bottle cap tester application requires higher torque capacities, we recommend one of our TFF Series reaction torque sensors. It is a family of +30 products with different heights, capacities, mounting flange, and cable configurations. Our sales engineers will guide your thru the selection of the sensor that best suits your application.

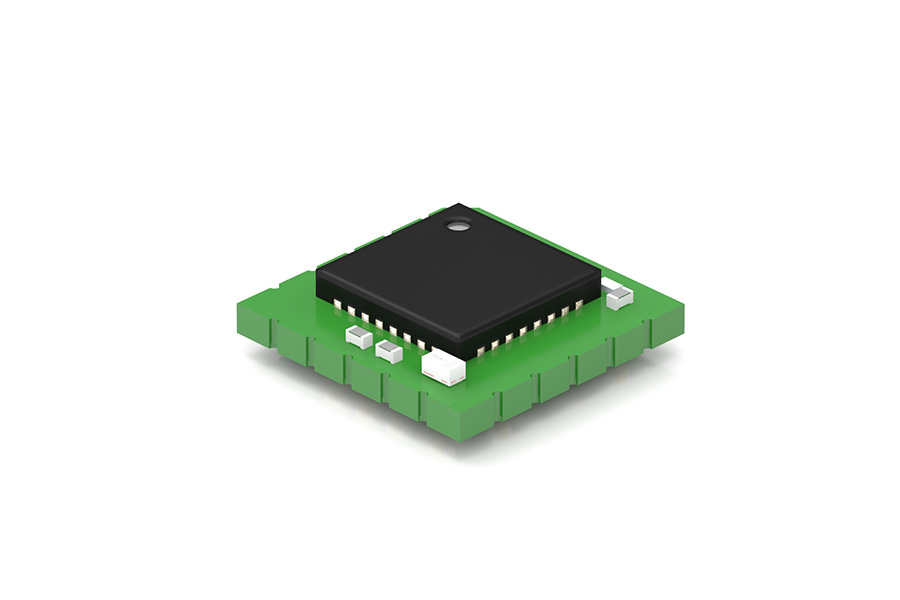

FUTEK QIA128 embedded digital signal conditioner

FUTEK QIA128 digital embedded signal conditioner is a miniature ultra low power digital signal conditioner with SPI output. Its miniature board of only 8 mm x 8 mm features a selectable sampling rate from 4 SPS to 1300 SPS to achieve from 11.4 up to 14.2 noise-free resolution (NFR) depending on requirements.

|