|

|

|

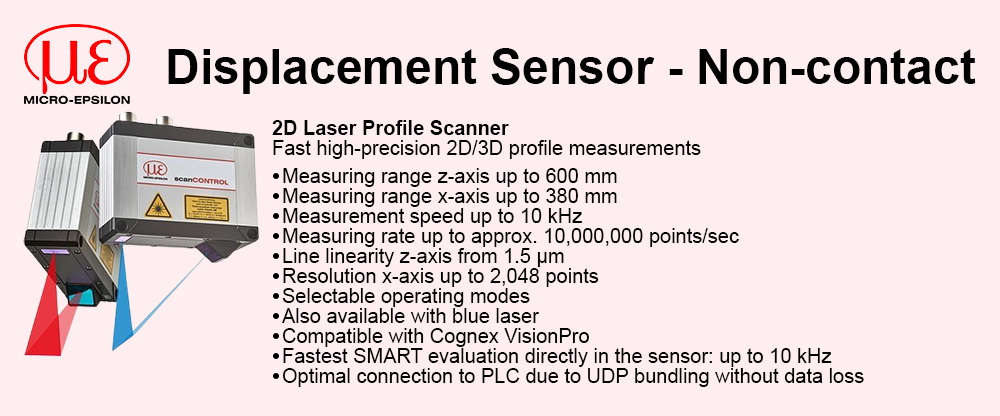

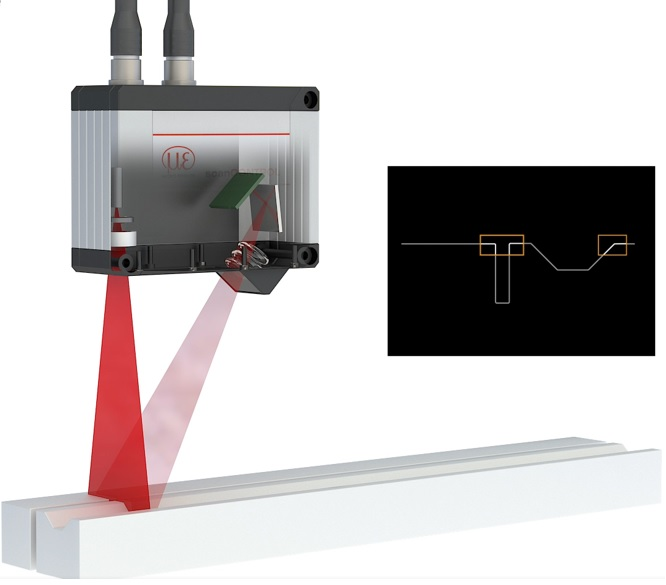

Laser scanners for 2D/3D profile measurements

|

|

Laser scanners from Micro-Epsilon are among the highest performing profile sensors in the world with respect to accuracy and

measuring rate. They detect, measure and evaluate profiles on different object surfaces without contact. The available

models are suitable for numerous industrial applications. The integrated intelligence in their sensor head (scanCONTROL SMART)

solves versatile measurement tasks. Models for the customer’s own programming are available for integrators.

The scanCONTROL profile scanners do not require any external controller.

|

|

|

What is scanCONTROL sensor measuring principle?

|

|

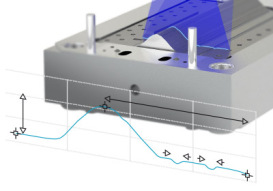

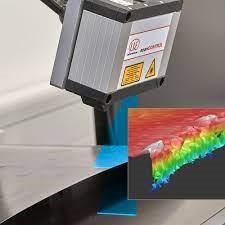

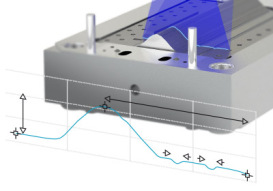

The scanCONTROL sensor operates according to the principle of optical triangulation (light intersection method):

A laser line is projected onto the target surface via a linear optical system A laser line is projected onto the target surface via a linear optical system

The diffusely reflected light from the laser line is replicated on a sensor array by a high quality optical system and evaluated in two dimensions The diffusely reflected light from the laser line is replicated on a sensor array by a high quality optical system and evaluated in two dimensions

The laser line triangulation corresponds in principle to the triangulation of a laser point. In addition, during the measurement a row of lines are simultaneously illuminated by the laser line. Apart from the distance information (Z-axis), the exact position of each point on the laser line (X-axis) is also acquired and output by the system.

|

|

|

|

|

|

|

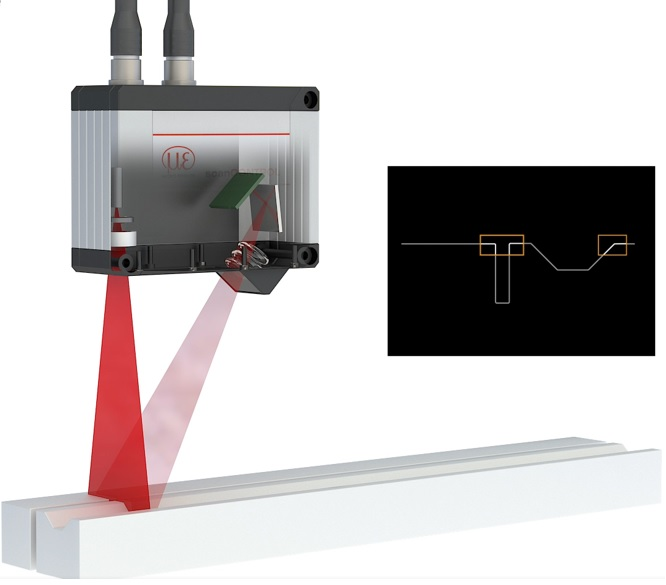

scanCONTROL stands out due to its compact design. A special line-scanning optical system ensures uniform exposure of the measuring field scanCONTROL stands out due to its compact design. A special line-scanning optical system ensures uniform exposure of the measuring field

The sensor array is arranged in the sensor head according to the Scheimpflug condition which facilitates uniform image focusing over the whole depth of the measurement range (Z-axis) The sensor array is arranged in the sensor head according to the Scheimpflug condition which facilitates uniform image focusing over the whole depth of the measurement range (Z-axis)

The scanCONTROL series with integrated profile analysis works even without a PC in conjunction with saved configurations. The sensor runs the profile measurement internally and calculates default measured values such as angle or edge position. Besides measurement value output via Ethernet (Modbus TCP protocol, UDP protocol) and RS422 (Modbus RTU protocol or ASCII format), additional switching signals (results of the determination of limit values) and analog measurement values can be output. This is done by an optional 2D/3D Output Unit, which transforms the determined measurement signals in switching and analog signals for further processing in a PLC The scanCONTROL series with integrated profile analysis works even without a PC in conjunction with saved configurations. The sensor runs the profile measurement internally and calculates default measured values such as angle or edge position. Besides measurement value output via Ethernet (Modbus TCP protocol, UDP protocol) and RS422 (Modbus RTU protocol or ASCII format), additional switching signals (results of the determination of limit values) and analog measurement values can be output. This is done by an optional 2D/3D Output Unit, which transforms the determined measurement signals in switching and analog signals for further processing in a PLC

2D/3D Gateway allows for scanCONTROL SMART sensors to be integrated into various fieldbus systems(PROFINET, EtherNet/IP, EtherCAT) 2D/3D Gateway allows for scanCONTROL SMART sensors to be integrated into various fieldbus systems(PROFINET, EtherNet/IP, EtherCAT)

|

|

|

Advantages

|

|

External synchronization and triggering External synchronization and triggering

Serial interface (RS422) for communication with PLC or PC Serial interface (RS422) for communication with PLC or PC

Digital switching inputs, selectable TTL or HTL Digital switching inputs, selectable TTL or HTL

The automatic control of the exposure time enables consistent measurement results with changing surfaces. This function can be switched off on request The automatic control of the exposure time enables consistent measurement results with changing surfaces. This function can be switched off on request

Ethernet 100/1000 Mbit as fast standard connection to PC Ethernet 100/1000 Mbit as fast standard connection to PC

|

|

|

Characteristics

|

|

Compact size and integrated evaluation: no external controller required Compact size and integrated evaluation: no external controller required

High profile resolution for the detection of finest details High profile resolution for the detection of finest details

High profile rate for dynamic measurement tasks High profile rate for dynamic measurement tasks

Powerful software for parameterization and visualization Powerful software for parameterization and visualization

SDKs for integration in individual software environments SDKs for integration in individual software environments

Proven high operational safety in the 24/7 operation over many years Proven high operational safety in the 24/7 operation over many years

Compatible with Cognex VisionPro Compatible with Cognex VisionPro

|

|

|

One SMART scanner for all parameters

|

|

|

|

|

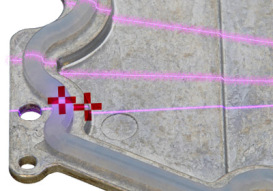

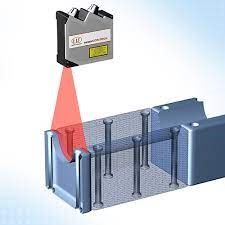

scanCONTROL laser scanners solve various measurement tasks: profile, width, height, depth, edge, bead, gap, angle, roundness and many more. With the Configuration Tools software, more than 40 measurement programs with a total of more than 90 evaluations are available. The programs are transferred to the SMART sensor, which performs the measurement, evaluation and output in standalone mode.

|

|

|

Intelligent SMART scanner: large range of features for numerous measurement tasks

|

|

|

|

|

|

|

|

|

Integrated evaluation, calculation and output of profile data

|

|

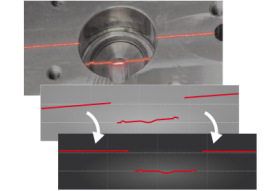

Simplifies alignment by adjusting tilted profiles

|

|

Tracking and measuring complex profiles, e.g., for inspection of adhesive beads

|

|

|

|

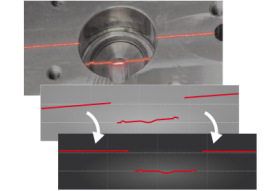

Profile scanners with red laser and patented Blue Laser scanners

|

|

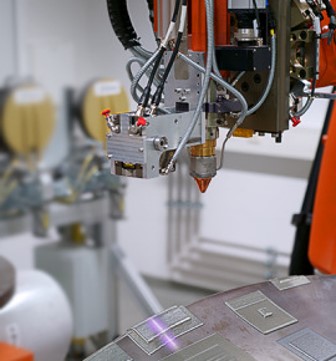

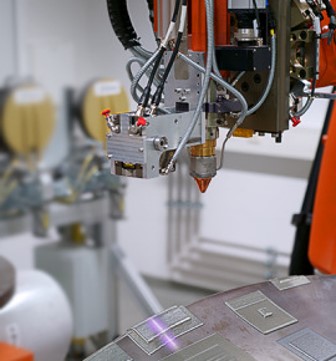

Laser scanners from Micro-Epsilon are available with a red laser diode or with the patented Blue Laser Technology. Laser scanners with blue laser line are preferably used for profile measurements on red-hot glowing metals, as well as transparent and organic surfaces. While allowing significantly higher stability, the blue-violet laser beam does not penetrate the measuring object.

Measurement tasks involving blue laser scanners measuring on red-hot glowing measurement objects exceeding 700 °C and transparent objects such as glass and plastics are protected by patent law. The scanCONTROL laser scanners achieve excellent signal stability and thus precise measurement results on these surfaces.

|

|

|

|

|

|

Compact profile sensors

|

|

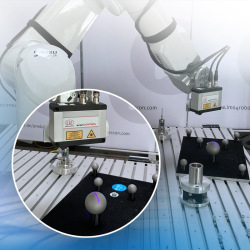

Compact size combined with low weight opens up new fields of application in profile measurement. The controllers of the scanCONTROL profile sensors being integrated in the housing simplify cabling arrangements and mechanical integration. Due to their compact size and their high profile frequency, the laser profile sensors are ideally suited to dynamic measurement tasks, e.g. in the production control or for robot mounting processes.

|

|

|

|

|

|

Flexible integration with two different classes

|

|

For raw profile transmission

|

With integrated profile calculation and evaluation

|

|

COMPACT |

SMART |

|

Various possibilities for data transmission

|

|

Ethernet (UDP or Modbus TCP) Ethernet (UDP or Modbus TCP)

RS422 (ASCII or Modbus RTU) RS422 (ASCII or Modbus RTU)

Analog, digital switching signals (with scanCONTROL Output Unit) Analog, digital switching signals (with scanCONTROL Output Unit)

Profinet, Ethernet/IP, EtherCAT (with scanCONTROL Gateway) Profinet, Ethernet/IP, EtherCAT (with scanCONTROL Gateway)

|

|

|

Applications

|

|

|

|

|

|

|