|

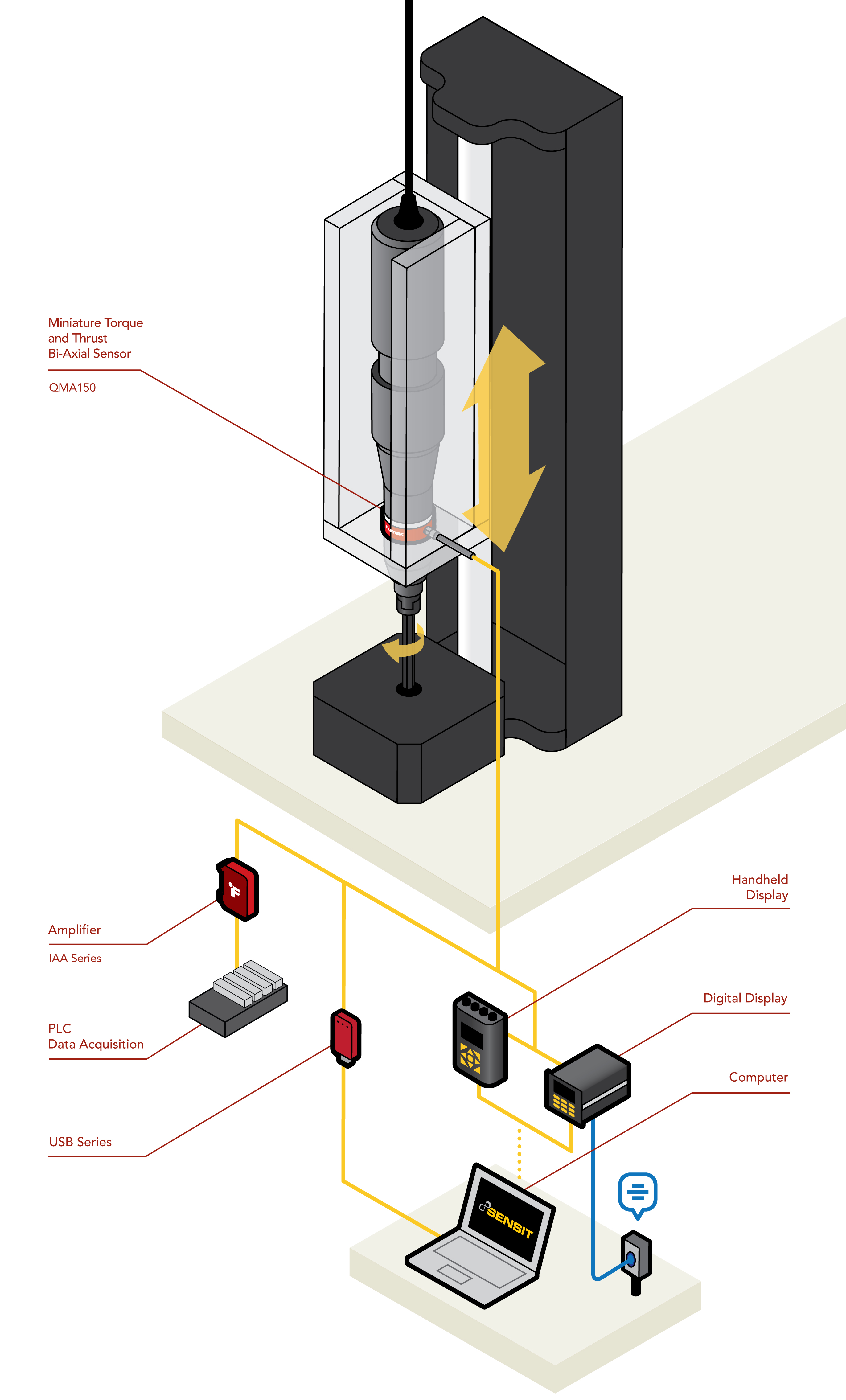

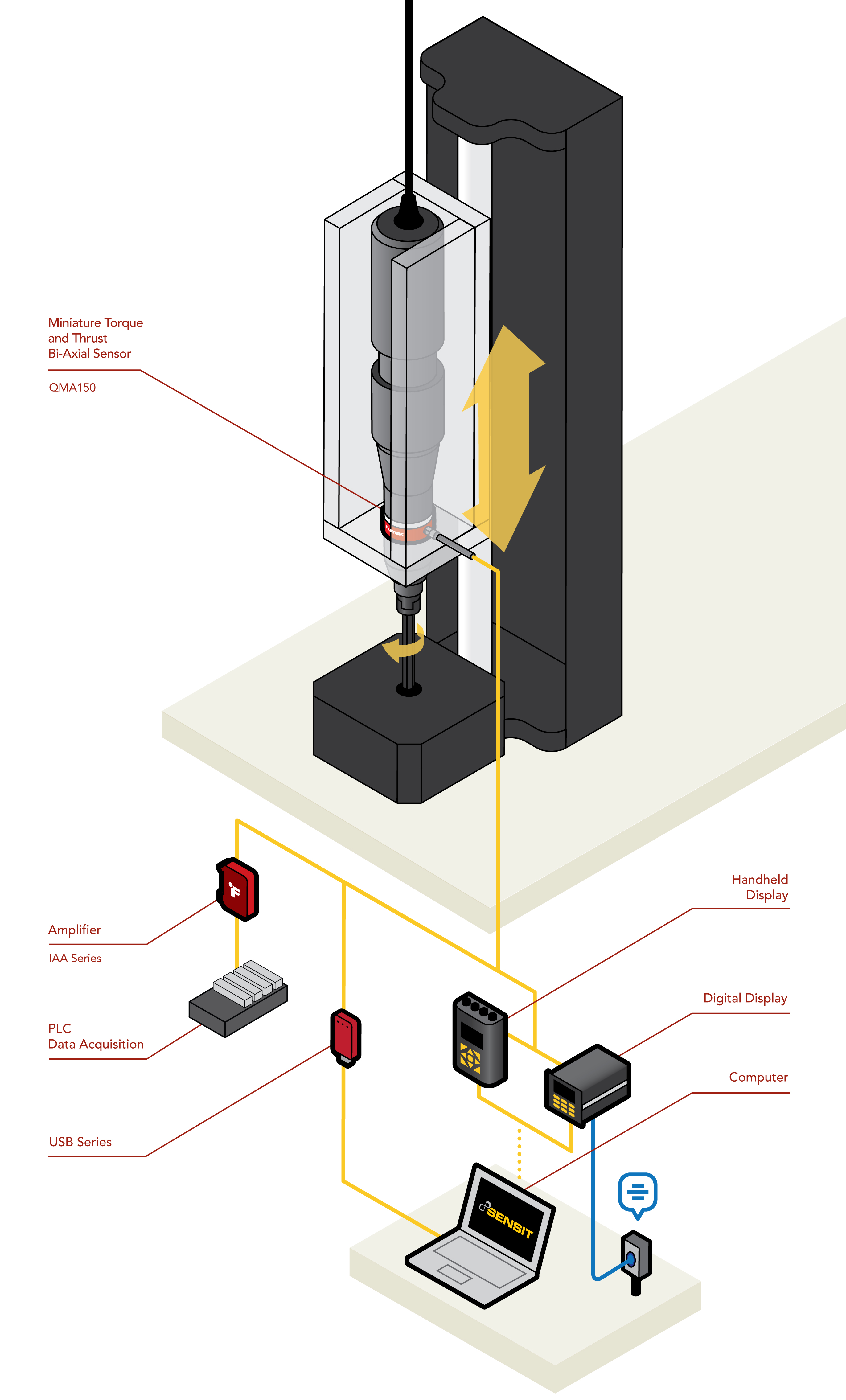

1. In this application, the QMA150 Torque and Thrust Biaxial Sensor is mounted in between the power drill and the holding guiding bracket. While the sensor is bolted to the power drill and the bracket, the drill bit is free to pass thru the sensor central hole. FUTEK's Engineers can customize a bi-axial sensor to be embedded into the power drill if the application requires.

2. As the power drill operates, the thrust force and reaction torque is measured by the bi-axial sensor. Different drilling conditions and materials cause different thrust and drilling forces, which is captured by the sensor.

3. These measurements are sent directly to a paired instrument which provides excitation voltage and conditions the signal (filtering, amplification, digitalization). Depending on signal conditioner selection, the operator can either view the data on a digital load display or stream the data directly onto a PC or a PLC/DAQ for data logging, control loop safety interlock or alarming.

4. Based on the drilling measurement data, operators and manufacturing engineers can optimize the process, prevent process failures, predict power drill or drill bit maintenance or replacement, and investigate the drilling process parameters, including cutting speed, feed rate, drill bit geometry, and composition, on the output product quality.

|

|

|